The Automated Universal Part Singulator project was implemented to revolutionize automated flexible part sorting for manufacturing applications. The project addresses limitations and inefficiencies that are present in currently used vibratory bowl feeder designs, such as size and shape limitations, part jamming, part damaging, and limited flexibility. These issues with vibratory bowl feeder designs highlight the need for more advanced, adaptable solutions that can overcome these limitations and optimize part singulation processes in different manufacturing industries.

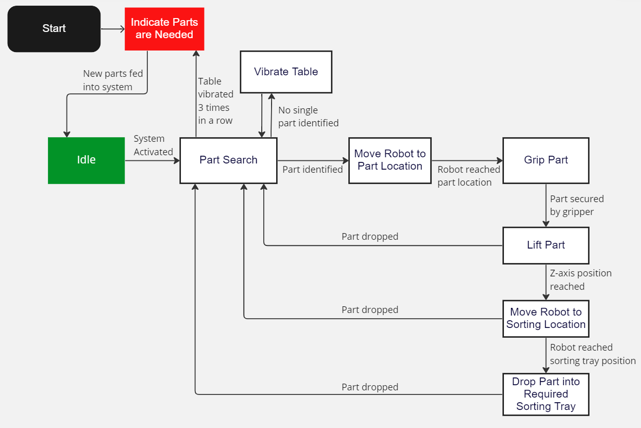

By incorporating sensors, robotics, and adaptive controls algorithms, the Automated Universal Part Singulator offers a flexible and efficient solution. It ensures precise separation and alignment of parts, reducing manual labor by leveraging advanced automation technologies. Moreover, the singulator's adaptability to handle various part shapes and sizes eliminates the need for multiple specialized singulation equipment, saving on equipment costs and maintenance.

The Automated Universal Part Singulator project was developed by a multidisciplinary team of six engineers with a diverse range of skills and expertise. This team consisted of two aerospace and mechanical engineers who brought knowledge of mechanical design to develop our gripper, vibration table, and frame subsystems. Additionally, two electrical and computer engineers contributed their proficiency in control systems, automation, and software development ensuring seamless integration of sensors, robotics, and controls algorithms. The team was further strengthened by the expertise of an optical engineer, who played a pivotal role in enhancing the vision systems and optical sensing capabilities. Additionally, a systems engineer acted as the project's procurement lead, skillfully managing the budget and ensuring optimal resource allocation. Through their collective efforts and collaborative approach, this exceptional team successfully created a groundbreaking solution that revolutionizes flexible part singulation in the manufacturing industry.

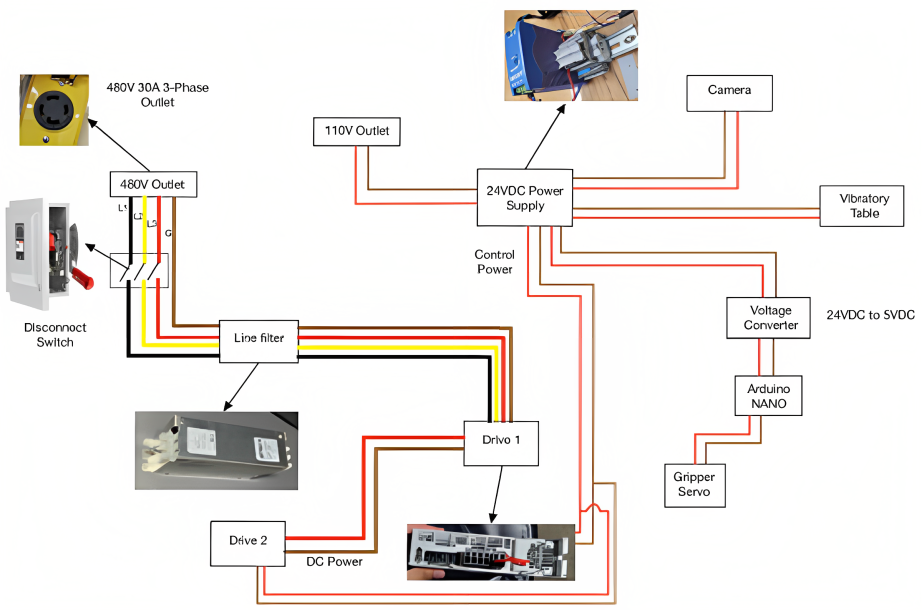

The project was completed for the University of Arizona Senior Design capstone and was sponsored by Bosch Rexroth. Bosch Rexroth's generous support included the provision of the Cartesian Actuator, a crucial component that enabled precise and efficient movement in the singulator system. Additionally, they supplied us with the CtrlX Machine Controller, which we used to program the controls algorithms for part singulation. Our project was further supported by CAID Automation who provided both guidance and the Cognex smart camera which served as the programmable vision system for the project. The exceptional efforts of our team, combined with the support of our sponsors, resulted in remarkable recognition. Our dedication and innovation led us to be honored with the prestigious "Best Overall Design" award at the University of Arizona's Design Day competition. This accolade stands as a testament to the tireless work, collaborative spirit, and outstanding design achieved by our team in developing the Automated Universal Part Singulator.

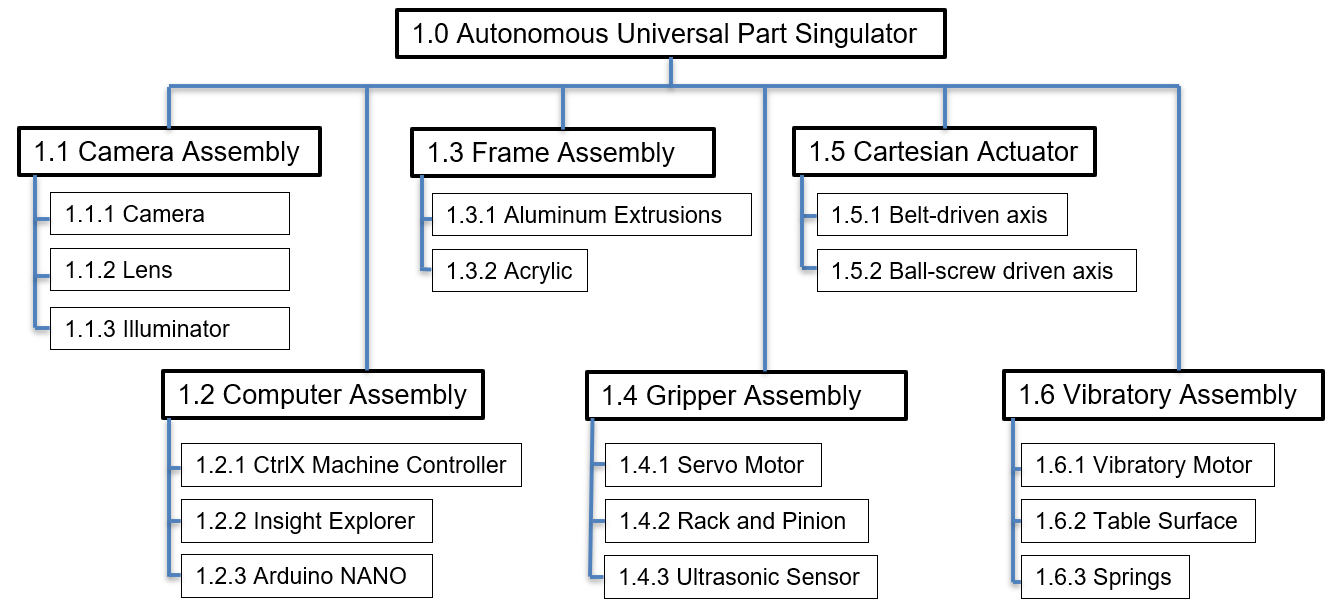

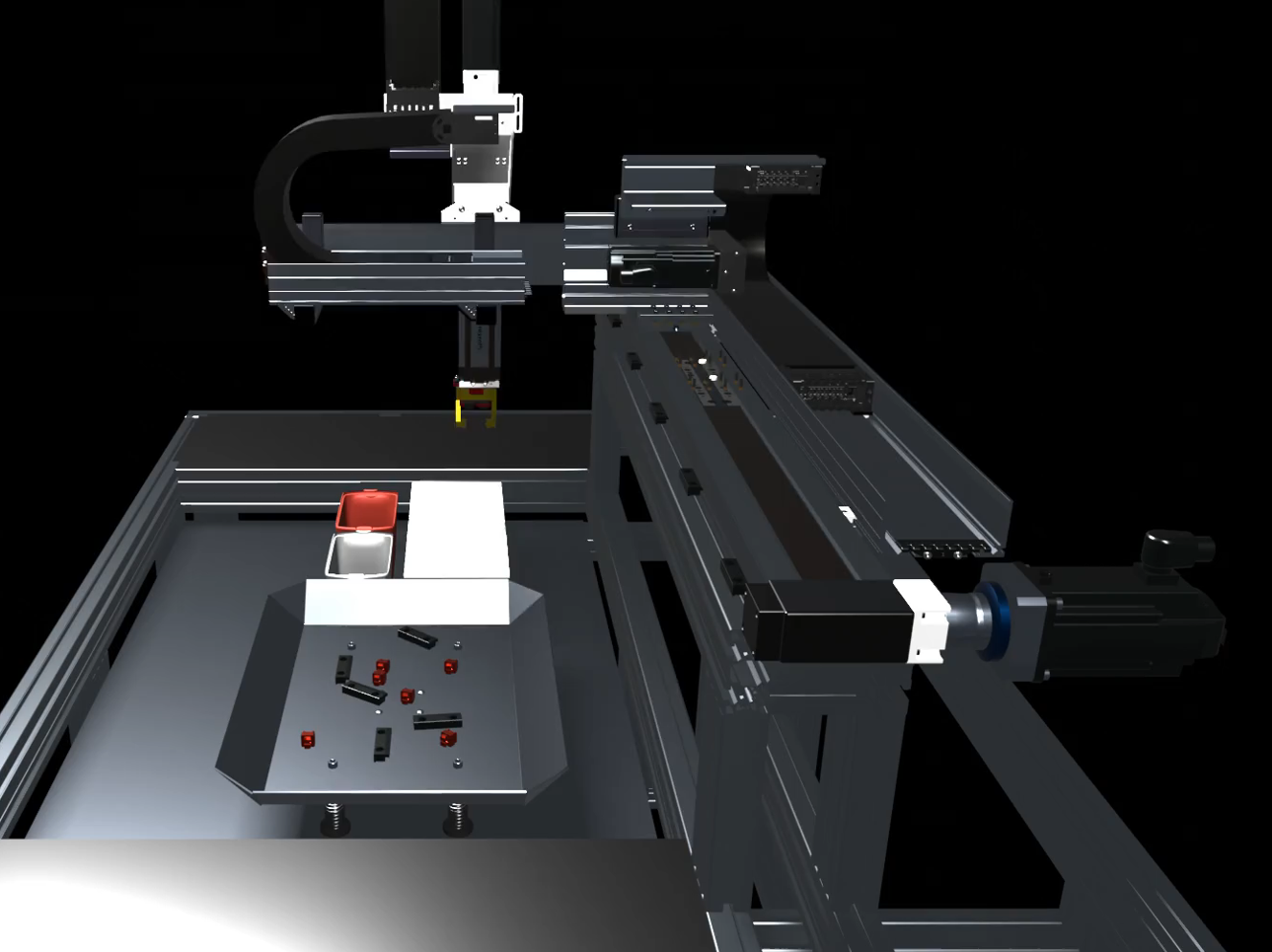

The Automated Universal Part Singulator comprises six major subsystems, each playing a critical role in its functionality and performance:

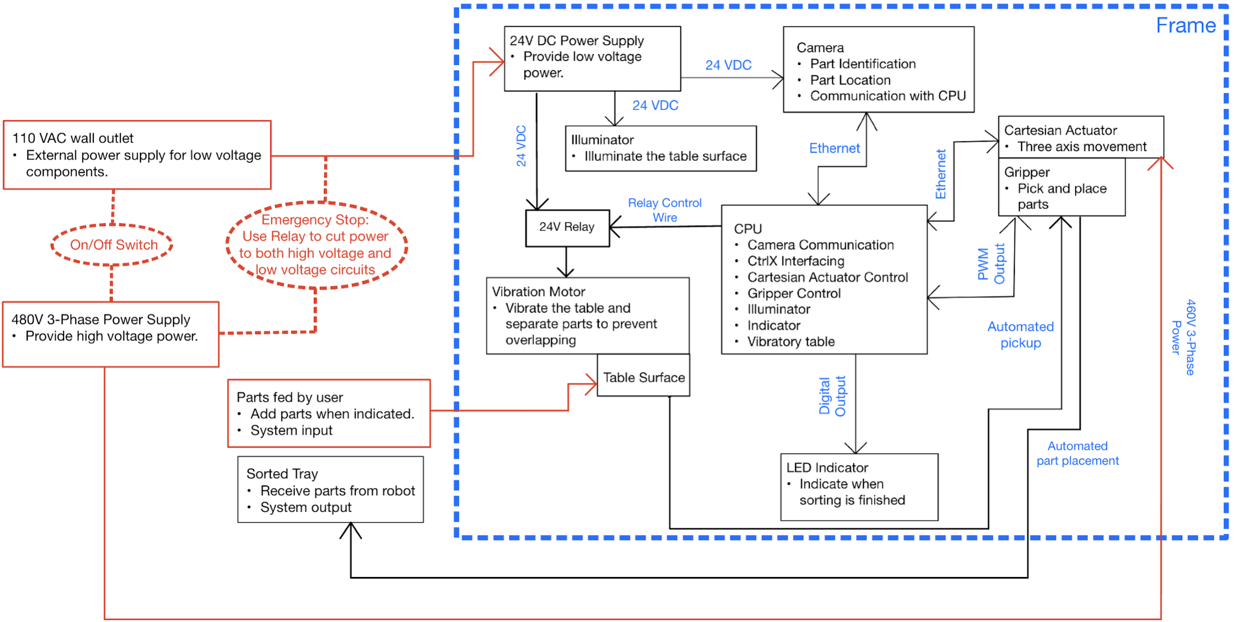

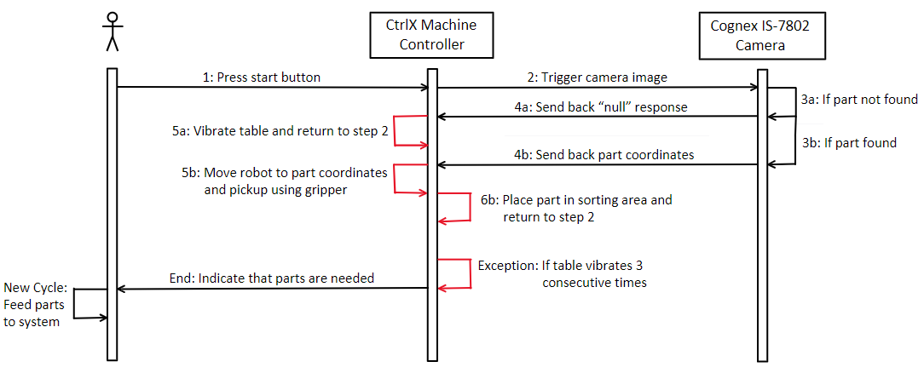

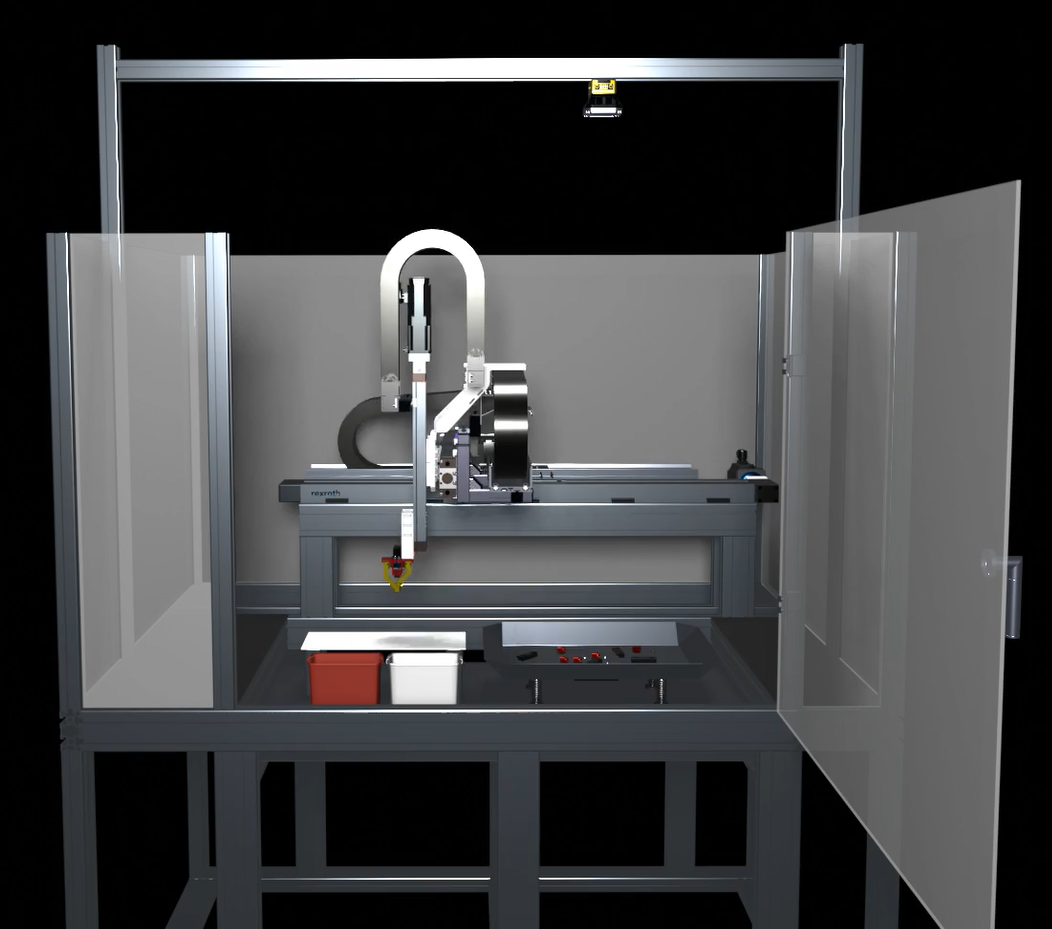

Camera Assembly: The camera assembly incorporates advanced vision technology, including the Cognex smart camera, to accurately identify and locate parts within the singulator system. It captures high-resolution images and provides real-time data for precise part identification, and pixel location. This served as the primary source of information for the control system.

Computer System: The computer system serves as the brain of the Automated Universal Part Singulator, housing the control software and algorithms. It processes pixel coordinate data from the smart camera, controls the operation of other subsystems, and ensures seamless integration and synchronization throughout the singulation process.

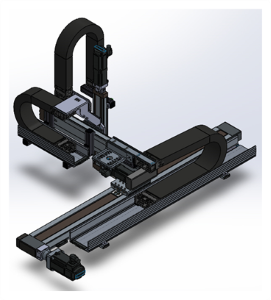

Frame Assembly: The frame assembly forms the structural backbone of the Automated Universal Part Singulator. It provides stability and rigidity to support the other subsystems and withstand the vibrations generated during operation. The frame assembly is designed for durability and precise alignment of the singulator components. It is surrounded by acrylic walls adding a safety shielding around the area of operation.

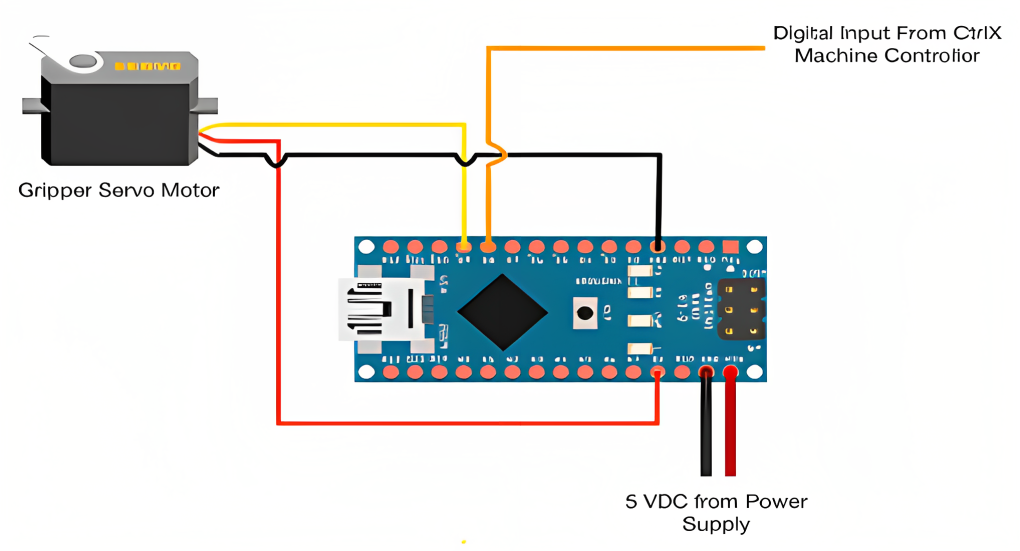

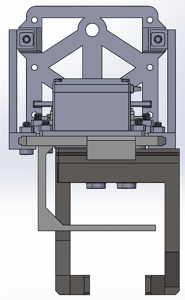

Gripper Assembly: The gripper assembly is responsible for securely gripping and releasing parts as they are singulated. It features a rack and pinion gear design that is controlled by an Arduino NANO to open and close the claws. The gripper assembly ensures reliable part security as parts are picked from the vibration table and transported to the appropriate placement location.

Cartesian Actuator: The Cartesian actuator, provided by Bosch Rexroth, features precision motion control. It utilizes linear motion to to pick and place parts using the gripper. The Cartesian actuator enables accurate and repeatable part manipulation, contributing to the overall efficiency and throughput of the Automated Universal Part Singulator.

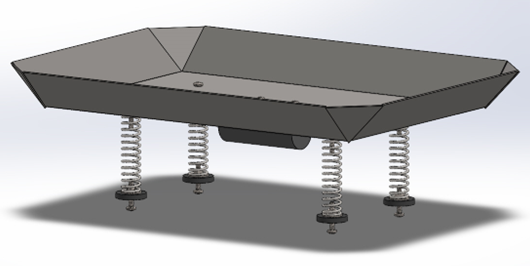

Vibration Assembly: The vibration assembly introduces controlled vibrations to assist in part dispersion on the vibration table. The assembly design features a vibration motor, compression springs, and a bowl shaped table to provide optimal part dispersion for part identification and singulation.